Ladder cable trays play a crucial role in modern high-rise buildings by providing structured pathways for electrical and data cables. These trays ensure that cables remain organized, accessible, and safely supported, especially in large buildings where cable networks are extensive. In high-rise construction, cable trays must meet specific load-bearing requirements to support heavy cable loads across multiple floors. This article explores the importance of ladder cable trays in high-rise infrastructure, detailing how load requirements are managed in alignment with industry standards.

Overview of Ladder Cable Trays in High-Rise Construction

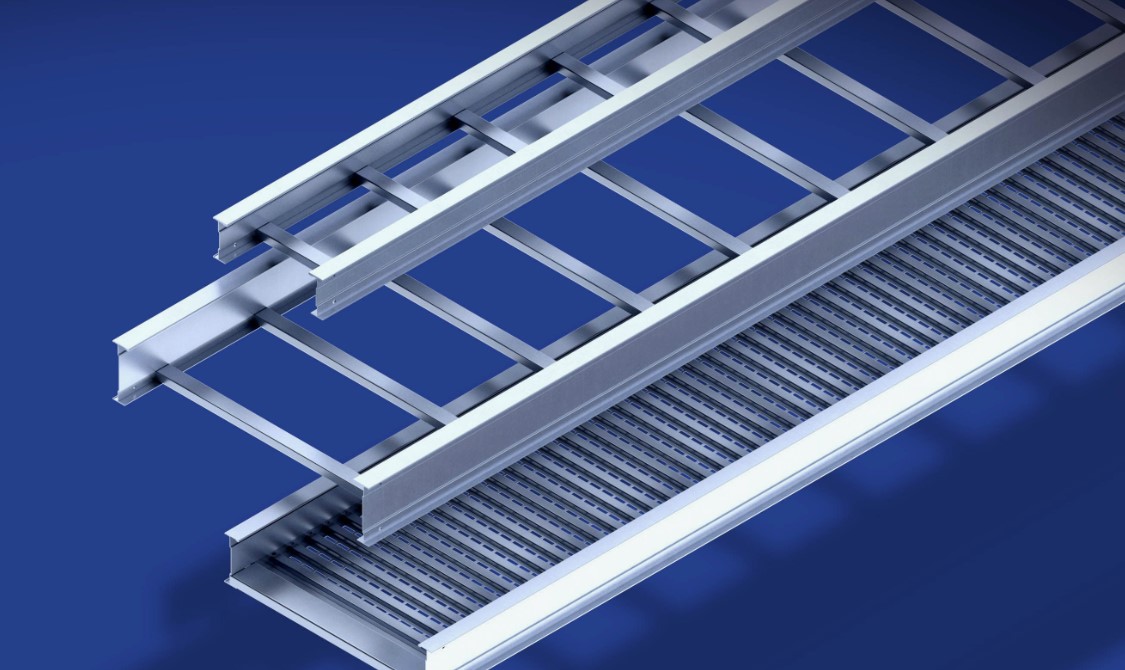

Ladder cable trays consist of side rails with crossbars that form a ladder-like structure, designed to support and organize electrical wiring. These trays are preferred in high-rise buildings because of their open design, which allows for effective heat dissipation, reducing the risk of overheating. The layout also facilitates easy installation and future upgrades by providing technicians with easy access to cables. This makes ladder trays an essential component in managing the complex electrical and communication networks typically required in large-scale buildings.

Understanding Load-Bearing Requirements

In high-rise construction, load-bearing requirements ensure that cable trays can withstand the cumulative weight of the cables over long spans without sagging or structural failure. These requirements are defined by factors such as cable weight, tray span length, and additional loads from fittings or clamps. Standards such as those provided by the National Electrical Manufacturers Association (NEMA) and IEC 61537 guide the load-bearing capacities for cable trays. Compliance with these standards ensures that installations in the UAE meet safety and performance expectations.

Factors Affecting Load-Bearing Capacity

1. Cable Weight and Type

The weight of the cables installed in a high-rise project influences the type and size of the ladder cable tray required. High-voltage cables, for example, are heavier than low-voltage or communication cables, requiring stronger trays to support the load. Planners must account for both current and future loads to avoid overloading the system during upgrades.

2. Span Length

The distance between the supports holding the cable tray is referred to as the span length. Longer spans require trays with higher structural integrity to prevent sagging under the weight of cables. Engineers must balance the tray strength with the practicality of support placements, ensuring that the structure is robust while minimizing unnecessary materials.

3. Environmental Factors

In regions like the UAE, where buildings are exposed to high temperatures, materials must be resistant to thermal expansion and contraction. Cable trays should also be able to handle additional loads from insulation, clamps, or protective covers. Corrosion resistance is another critical factor, particularly in coastal areas where high humidity and salinity can affect metal components.

Material Selection for Ladder Cable Trays

Steel, aluminum, and stainless steel are the most common materials used for ladder cable trays. Each material offers unique benefits, but in the UAE’s high-rise buildings, stainless steel is often preferred for its corrosion resistance and durability. Brands like BONNGULF offer high-quality stainless steel ladder cable trays that meet both load-bearing and environmental requirements, ensuring long-term performance under challenging conditions.

Installation Considerations for High-Rise Projects

Installing ladder cable trays in high-rise buildings involves several logistical considerations. Proper support systems must be planned to distribute the cable load evenly across floors. Engineers must also ensure that trays remain accessible for maintenance and future upgrades. Careful attention is required to secure the trays against movement due to building vibrations or environmental forces, ensuring the stability of the cable network over time.

Compliance with UAE Building Codes and Standards

The UAE enforces strict building codes to ensure the safety and functionality of electrical installations. These regulations align with global standards such as NEMA and IEC, ensuring that cable tray systems are properly installed to handle both mechanical and environmental stress. Compliance with these standards ensures that high-rise buildings in Dubai and the UAE meet the necessary safety requirements while maintaining high performance over time.

Fire Safety in Ladder Cable Tray Systems

High-rise buildings in the UAE must adhere to fire safety regulations outlined by the Dubai Civil Defence. Ladder cable trays play a key role in these safety measures by ensuring that electrical systems remain organized and accessible in case of emergencies. Fire-rated trays and fittings help contain potential cable fires, preventing the spread of flames across multiple floors. Using appropriate materials and following installation guidelines ensures compliance with fire safety standards.

Maintenance and Long-Term Performance

Proper maintenance is essential to ensure the long-term performance of ladder cable trays in high-rise buildings. Periodic inspections are necessary to identify any signs of corrosion, damage, or loose fittings. Regular maintenance also ensures that additional cables can be integrated seamlessly without exceeding the tray’s load capacity. Efficient cable management through structured pathways minimizes the risk of operational downtime and simplifies troubleshooting for maintenance teams.

Conclusion

Ladder cable trays are integral to high-rise buildings, providing reliable support for complex cable networks while meeting strict load-bearing and safety requirements. In Dubai and the UAE, where environmental conditions and fire safety regulations demand high performance from every infrastructure component, ladder cable trays are essential. By selecting appropriate materials, such as those provided by BONNGULF, and adhering to local and international standards, contractors can ensure the stability and longevity of electrical installations. Proper installation, regular maintenance, and compliance with regulations ensure that high-rise buildings remain safe and operational, meeting the demands of modern infrastructure.

Soccer lover, nature enthusiast, guitarist, Bauhaus fan and critical graphic designer. Doing at the fulcrum of minimalism and purpose to craft experiences that go beyond design. I am 25 years old.